GLUED FLOORS WITH UNDERFLOOR HEATING

COMMERCIAL/RESIDENTIAL

E 4.3

E 4.3

UNDERFLOOR HEATING INFORMATION

|

E 4.0 |

General Information |

|

E 4.3 |

Glued floors with |

Table 1

GENERAL INFORMATION

These instructions apply to Junckers solid hardwood floors glued to:

- Sub floors of concrete with embedded heating pipes or cables.

- Sub floors of concrete with heating cable mats

- Grooved chipboard with heating pipe and pressure distribution board

Please note that full documentation comprises General information about underfloor heating and this document, see table 1.

See also C 1.0 General information, Junckers solid hardwood floors for commercial and residential areas.

If questions, please contact Junckers Technical Service Department.

CLIMATIC CONDITIONS

Before commencing the installation of the flooring, the temperature and humidity of the building should correspond to the expected future climatic conditions of the building when in use, e.g. 35 - 65 % relative humidity, approx. 20 °C.

This may be achieved by operating the underfloor heating system to the extent necessary, according to circumstances. During this period, the building should be ventilated briefly every day.

In concrete and screeded subfloors, etc., with embedded underfloor heating systems, the residual moisture content in the concrete or screed must not exceed 85 % relative humidity (UK: 75 %) and Junckers Liquid Moisture Barrier must be applied before gluing. See data sheet C 1.3, Measurements of moisture in subfloors.

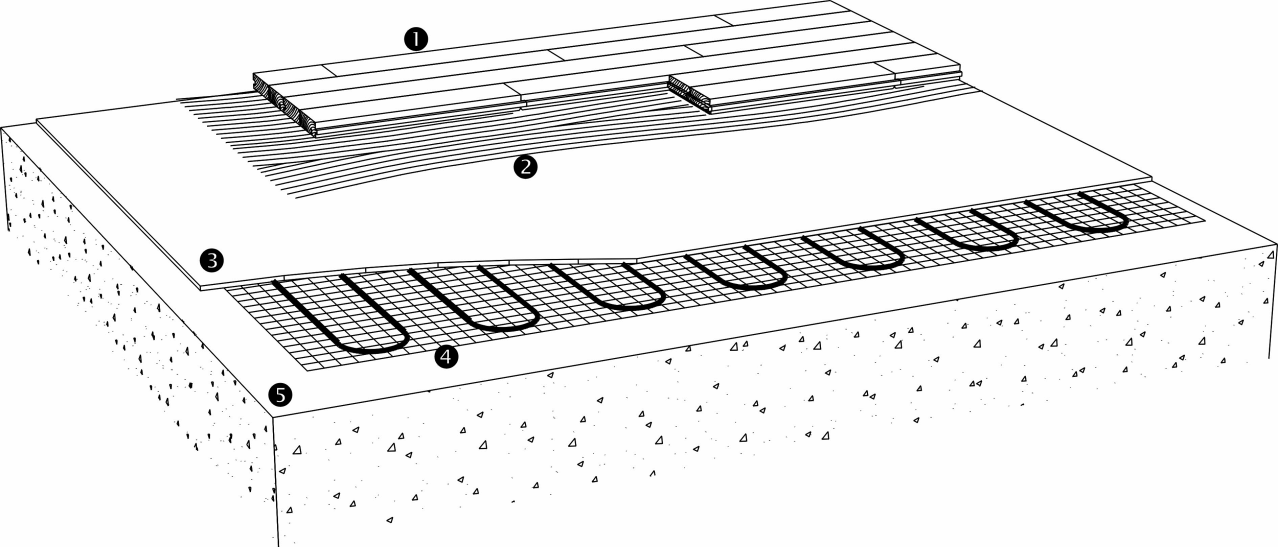

1. SUBFLOORS OF CONCRETE WITH EMBEDDED HEATING PIPES OR CABLES

It is extremely important to design the underfloor heating system in such a way as to achieve a regular temperature distribution across the top surface of the subfloor.

Regular temperature distribution is achieved at a pipe/cable embedding depth of min. 30 mm and a pipe spacing of 300 mm c/c or a cable spacing of 150 mm c/c.

During installation, the underfloor heating system must be turned off to aid adhesive workability.

1.1 FLOOR COMPONENTS

- Juncker Solid Hardwood floor

Choose between 2-strip or planks, Single staves, Whalebone, Hexparket, Twin Herringbone.

See complete product range in chapter B. -

Adhesive and moisture barrier

Junckers Parquet Glue

Juncker Liquid Moisture Barrier -

Concrete or screeded subfloor

-

Heating pipes/cables

-

Reinforcement

-

Insulation

-

Structural concrete floor

Fig. 1

2. SUBFLOORS OF CONCRETE WITH HEATING CABLE MATS

It is extremely important to design the underfloor heating system in such a way as to achieve a regular temperature distribution across the top surface of the subfloor.

In order to protect the heating cables and ensure a regular heat distribution, the heating cable mat must be covered by a cementitious layer, min. 6 mm thick. Before installing the heating mat, the subfloor may need to be primed to ensure that the mat adheres correctly to the base.

When renovating floors where the heating system is placed on an existing, dry subfloor, the adhesive can be applied as soon as the cementitious layer is fully dry. Follow the instructions of the manufacturer.

For new concrete subfloors, gluing of floorboards can be started according to instructions mentioned under climatic conditions.

During installation, the underfloor heating system must be turned off to aid adhesive workability.

2.2 FLOOR COMPONENTS

- Juncker Solid Hardwood floor

Choose between 2-strip or planks, Single staves, Whalebone, Hexparket, Twin Herringbone.

See complete product range in chapter B. - Adhesive

Junckers Parquet Glue

Junckers Moisture Barrier - Cementitious layer

Min. 6 mm - Heating cable mat

- Structural concrete floor

Fig. 2

3. GROOVED CHIPBOARD WITH HEATING PIPE AND PRESSURE DISTRIBUTING BOARD

Pressure distributing board with tongue and groove in thickness of at least 15 mm is laid on a grooved chipboard with heat distributing boards and heating pipes.

500 g of cardboard is laid as an intermediate layer between the pressure distributing board and grooved chipboard with heat distribution boards and heating pipes.

During installation, the underfloor heating system must be turned off to aid adhesive workability.

3.3 FLOOR COMPONENTS

-

Junckers Solid Hardwood floor

Choose between 2-strip or planks, Single staves, Whalebone, Hexparket, Twin Herringbone.

See complete product range in chapter B. -

Adhesive

- Junckers Parquet Glue -

Min. 15 mm pressure distributing board over 500 g of cardboard

-

Grooved chipboard, heating pipes and heat distributing boards

-

Batten construction, Follow instructions from chipboard supplier regarding batten center.

-

Subfloor with moisture barrier, 0,2 mm PE-foil

Fig. 3